One of the last things you want to have to deal with is scratched platters in your hard drive. That is if you really do care about the data you have stored on it. In many cases, scratched platters spell the end of the road for that particular disc and the data it was storing. However, there are times when the data can still be salvaged… the link here will tell you all you need to know and the truth about scratched platters and the likelihood of recovery. But for today, I want to discuss the ‘why and how’ which will explore the actual process and a number of different ‘hows.’

Hopefully, I will be able to give you some insight on what to do and what not to do if your hard drive ends up with scratched platters or if you suspect that it does.

To begin, let’s look at the why.

Instant Shock, Knock, Kick, Bang To The Drive While Spinning/Working/Operating

Please note that I said ‘instant knock, kick or bang’ – NOT drop. Dropping in many cases, or in MOST cases actually, will not scratch the platters. That’s simply because of the design of modern hard drives. They have a special air detection system installed on the PCB that will recognize that the hard drive is suddenly airborne. When this is detected, the HSA is automatically moved into a parking position away from the platters. Knocking or kicking it though can be instant and the drive may not be able to react to the kick or shock. That results in a possibility that the heads may come in contact with the platters and cause round scratches.

This happens to be the most common reason platters get scratched and it is quite simply the most common of the regular user type scenario. In other words, it happens by accident and not on purpose. This doesn’t mean that you can rest easy knowing that if you drop a working drive that it’ll survive the fall. The chances that the platters will be okay are pretty high by not quite as high as in the case of an instant shock.

Dust Or Debris

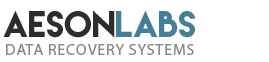

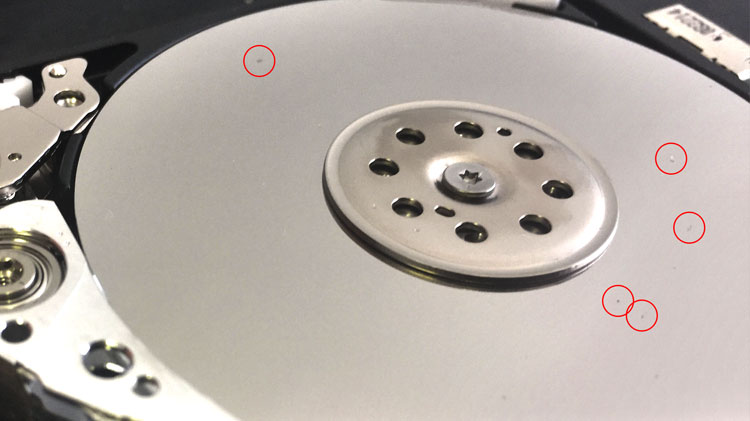

Dust that got inside the drive and worked its way in-between the head and the platter can be a problem. Your drive can be just sitting at your desk for decades and all of a sudden you hear it start to click loudly for no apparent reason. Its either going to be the result of headwear or there has been a dust particle or some form of debris that ended up between the head and the platter. Believe it or not, that will be enough to cause a scratch. I will explain later the ‘how’ process and as it turns out, the ‘how’ process does involve dust.

So, how does dust end up in hard drives if they are factory sealed? It’s a fair question you may have. First, hard drives have breathing holes in them and this is usually how the dust gets inside. The other ways in which dust and debris can end up in a hard drive include the constant movement of the metal and plastic parts inside. Some plastic will create dust particles 100% of the time and that may explain why filters are inside hard drives. Essentially, there is no possible way to have a dust-free hard drive – even in a cleanroom facility.

Now to look at the ‘how’ and the process that creates the scratches.

Let’s start with something called the flying height of the head.

What is that, right?

The flying height – or head gap – is the distance between the disk read/write head on a hard disk drive and the platter. The very first commercial hard disk drive, the IBM 305 RAMAC, used forced air to maintain a 0.002 inch (51 um) spacing between the head and disk.

Think about what 0.002 inches are. That is tiny. When you consider the small distance here, it is not hard to imagine that a slight shock can and most likely will bring the head into contact with the platter. A tiny grain of salt measuring 0.3 mm (0.011811 inches) can bring havoc inside your drive as well by creating that involuntary connection between platter and head. But what are the chances that something is going to get into your drive without it getting opened? Pretty slim but those dust grains inside your hard drive can vary between 5 to 1,000 microns. 5 microns equals 0.00019685 inches and 1,000 microns equals 0.0393701 inches. So, anywhere after the 50-micron mark is the danger zone for your platters.

So, the ‘how’ can only be a single ‘how’ where the head contacts the platter directly and causes round scratching. I’ve already explained the differences.

This is why it is a bad idea to open up a drive outside of a clean room, dust-free environment. You really have no idea how much dust exists around us – in your room, in your workplace, everywhere – you can clearly see dust particles floating around when in a dark room with the sun shining in from a single window.

All of that dust you see – thanks to the sun reflecting off of it – can potentially end up in your hard drive.

Hopefully, you now have a better understanding of this topic.